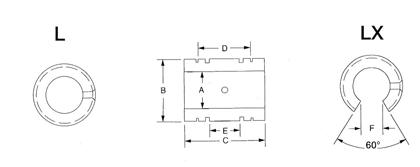

Self-Lubricating Linear Bearings are made with a PTFE composite liner that eliminates the need for liquid lubrication. These bearings run quieter and run better in contamination environments than traditional linear ball bearings. They are designed to be dimensionally compatible drop-in replacements for linear ball bearings. Closed Bearings are to be used with end-supported shafts. Open Bearings are to be used for applications requiring maximum rigidity. (Used with shafts with support rail.)

PTFE lined bearings have a chemical-resistant PTFE liner (PTFE-filled composite) for wear resistance and strength. Temperature range is –400° to +385° F. For use with shafts that have a hardness of at least Rockwell C35 and an 8-12 Ra micron finish.

Self-Lubricating Linear Bearing Products

|

apt bearing |

Nominal Bore Size |

Working Bore A |

ID Bore – .000 |

Outside B |

OD + 0 |

Bearing C |

Length +0 |

Distance D |

Distance E |

Bearing |

|||

|

AL 04 |

1/4″ |

0.2505 |

0.001 |

0.5 |

0.001 |

0.75 |

0.015 |

0.437 |

0.018 |

0.009 |

|||

|

AL 06 |

3/8″ |

0.3755 |

0.001 |

0.625 |

0.001 |

0.875 |

0.015 |

0.562 |

0.26 |

0.016 |

|||

|

AL 08 |

1/2″ |

0.5005 |

0.001 |

0.875 |

0.001 |

1.25 |

0.015 |

0.875 |

0.49 |

0.041 |

|||

|

AL 10 |

5/8″ |

0.6255 |

0.001 |

1.125 |

0.001 |

1.5 |

0.015 |

1 |

0.55 |

0.091 |

|||

|

AL 12 |

3/4″ |

0.7508 |

0.001 |

1.25 |

0.001 |

1.625 |

0.015 |

1.062 |

0.612 |

0.109 |

|||

|

AL 16 |

1″ |

1.0008 |

0.001 |

1.5625 |

0.001 |

2.25 |

0.015 |

1.625 |

1.18 |

0.228 |

|||

|

AL 20 |

1-1/4″ |

1.2508 |

0.001 |

2 |

0.001 |

2.625 |

0.02 |

1.875 |

1.425 |

0.459 |

|||

|

AL 24 |

1.5″ |

1.5008 |

0.0015 |

2.375 |

0.0015 |

3 |

0.02 |

2.25 |

1.67 |

0.75 |

|||

|

AL 32 |

2″ |

2.0012 |

0.0015 |

3 |

0.0015 |

4 |

0.02 |

3 |

1.45 |

1.442 |

|||

|

AL 40 |

2.5 |

2.5012 |

0.0015 |

3.75 |

0.0015 |

5 |

0.025 |

3.75 |

1.6 |

2.816 |

|||

|

AL 48 |

3″ |

3.0012 |

0.002 |

4.5 |

0.002 |

6 |

0.03 |

4.5 |

2.19 |

4.914 |

|||

|

AL 64 |

4′ |

4.0042 |

0.002 |

6 |

0.002 |

8 |

0.04 |

6 |

11.836 |

|

apt bearing |

Nominal Bore Size |

Working A |

ID Bore – .000 |

Outside B |

OD + 0 |

Bearing C |

Length +0 |

Slot |

Distance D |

Distance E |

Bearing |

|

||

|

ALN 04 |

1/4″ |

0.2505 |

0.001 |

0.5 |

0.001 |

0.75 |

0.015 |

0.094 |

0.437 |

0.018 |

0.008 |

|||

|

ALN 06 |

3/8″ |

0.3755 |

0.001 |

0.625 |

0.001 |

0.875 |

0.015 |

0.156 |

0.562 |

0.26 |

0.013 |

|||

|

ALN 08 |

1/2″ |

0.5005 |

0.001 |

0.875 |

0.001 |

1.25 |

0.015 |

0.312 |

0.875 |

0.49 |

0.034 |

|||

|

ALN 10 |

5/8″ |

0.6255 |

0.001 |

1.125 |

0.001 |

1.5 |

0.015 |

0.375 |

1 |

0.55 |

0.072 |

|||

|

ALN 12 |

3/4″ |

0.7508 |

0.001 |

1.25 |

0.001 |

1.625 |

0.015 |

0.438 |

1.062 |

0.612 |

0.091 |

|||

|

ALN 16 |

1″ |

1.0008 |

0.001 |

1.5625 |

0.001 |

2.25 |

0.015 |

0.563 |

1.625 |

1.18 |

0.184 |

|||

|

ALN 20 |

1-1/4″ |

1.2508 |

0.001 |

2 |

0.001 |

2.625 |

0.02 |

0.625 |

1.875 |

1.425 |

0.381 |

|||

|

ALN 24 |

1.5″ |

1.5008 |

0.0015 |

2.375 |

0.0015 |

3 |

0.02 |

0.75 |

2.25 |

1.67 |

0.63 |

|||

|

ALN 32 |

2″ |

2.0012 |

0.0015 |

3 |

0.0015 |

4 |

0.02 |

1 |

3 |

1.45 |

1.192 |

|||

|

ALN 40 |

2.5″ |

2.5012 |

0.0015 |

3.75 |

0.0015 |

5 |

0.025 |

1.25 |

3.75 |

1.6 |

2.334 |

|||

|

ALN 48 |

3″ |

3.0012 |

0.002 |

4.5 |

0.002 |

6 |

0.03 |

1.5 |

4.5 |

2.19 |

4.08 |

|||

|

ALN 64 |

4′ |

4.0042 |

0.002 |

6 |

0.002 |

8 |

0.04 |

2 |

6 |

9.87 |

- Add replace ALN with ALCN for increased running clearance on bearing bore.

- For Self-Aligning, add SA to end of PN. (i.e. ALCN 04 SA)

(Except for the O.D., bearings with the self-aligning feature have the same dimensions and tolerances as the standard bearings. There is a spherical crown on the OD which allows the bearing to self-align within a straight bored housing.)

In addition to the product above, we may also have a solution for the following competitor part numbers as well: 5986K761, 5986K764, 5986K767, 5986K771, 5986K774, 5986K781, 5986K784, 5986K787, 5986K791, 6676K71, 6676K72, 6676K73, 6676K74, 6676K75, 60605K91, 60605K92, 60605K93, 60605K94, 60605K95, 60605K96, 60605K97, 6396K31, 6396K32, 6396K33, 6396K34, 6396K35, 6396K36, 6396K37, 6396K38, 8356K12, 8356K13, 8356K14, 8356K15, 6676K61, 6676K62, 6676K63, 6676K64, 6676K65, 2570K11, 2570K12, 2570K13, 2570K4, 6673K11, 6673K12, 6673K13, 6673K14, 6673K15, 6673K35.